Left hand holds chisel, and right hand strikes chisel with hammer.

The right amount of force from both hands is important for creating engraving level and beauty and depends on a number of factors such as angle and pressure at which chisel is held, or strength of hammer blow.

Kubota-san's designs are inspired by traditional Japanese cultures and beautiful landscapes. Kanji character is relatively easy to engrave, as it consists largely of straight lines. With practice, even a novice can do it. Hiragana, on the other hand, is much more difficult to engrave.

As it consists of a curved line and a small number of strokes, it's very important to maintain the overall balance of the letters. In addition, right hand pressure must be applied for the chisel to work smoothly.

Beauty lies in precise quality. Engraving is very demanding on eyes and fingers. Meticulous work demands great concentration and attention. Dragon scales, tiger fur, fish bubbles, cherry blossom petals...even a single blow of hammer, when viewed in its entirety, can radically change the perspective.

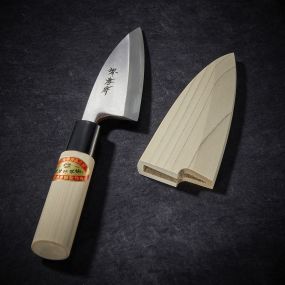

Blade offered here is that of a traditional Japanese Deba-style forged knife. This blade design depicts a scene inspired by Kyoto's springtime, the Maiko and cherry blossoms.

A maiko is a Kyoto geisha apprentice whose job is to perform songs and dances and play the shamisen or other traditional Japanese instruments for visitors at banquets and festivals, known as ozashiki. Maiko are generally aged between 17 and 20, and reach geisha status after a period of apprenticeship that includes traditional dance, shamisen, kouta (literally "short songs") and, in Kyoto only, learning the Kyoto dialect.

Apprenticeship lasts from a few months to a year or two, although apprentices who are too old to dress as maiko can become geisha while continuing their training.

Knives made from this steel have perfect cutting capacity, are easy to sharpen and retain their edge well.

Many experts consider the cut of this steel to be a benchmark, but like all carbon steels, it is not corrosion-resistant and requires careful maintenance. Typical hardness is between 60 and 64 HRc.

Rockwell HRC blade hardness: HRC60

Knife quality: HRC-Rockwell hardness of Aoki Hamono knives.

HRC value, degrees Rockwell C, expresses knife blade hardness, which varies according to steel used to make knives.

All very inexpensive knives have an HRC value well below 52. Blades wear out very quickly, as they are too flexible. High-quality knives, such as Aoki Hamono, have an HRC value of 58 to 63. Their cutting edge is of the highest quality and is preserved much longer.

Safety precautions: Sharpening with a whetstone is recommended. Remember that knives should be washed after each use, in hot water, with a natural soap and never with a dishwashing liquid. They should be dried immediately, then ideally lightly oiled with vegetable oil (olive oil or neutral vegetable oil).

Recommendation: KNIVES AND SHARP OBJECTS CAN BE PARTICULARLY HAZARDOUS AND MUST BE USED WITH CARE. THEY MUST NOT BE LEFT WITHIN THE REACH OF CHILDREN OR PERSONS NOT CAPABLE OF USING THEM OR APPRECIATING THEIR DANGEROUSNESS.